Un horno de templado de vidrio es un equipo especializado que se utiliza en la industria de fabricación de vidrio para templar el vidrio, haciéndolo más resistente y seguro que el vidrio sin tratar. El templado implica calentar el vidrio a una temperatura alta y luego enfriarlo rápidamente para crear tensiones internas, lo que da como resultado una mayor resistencia y durabilidad.

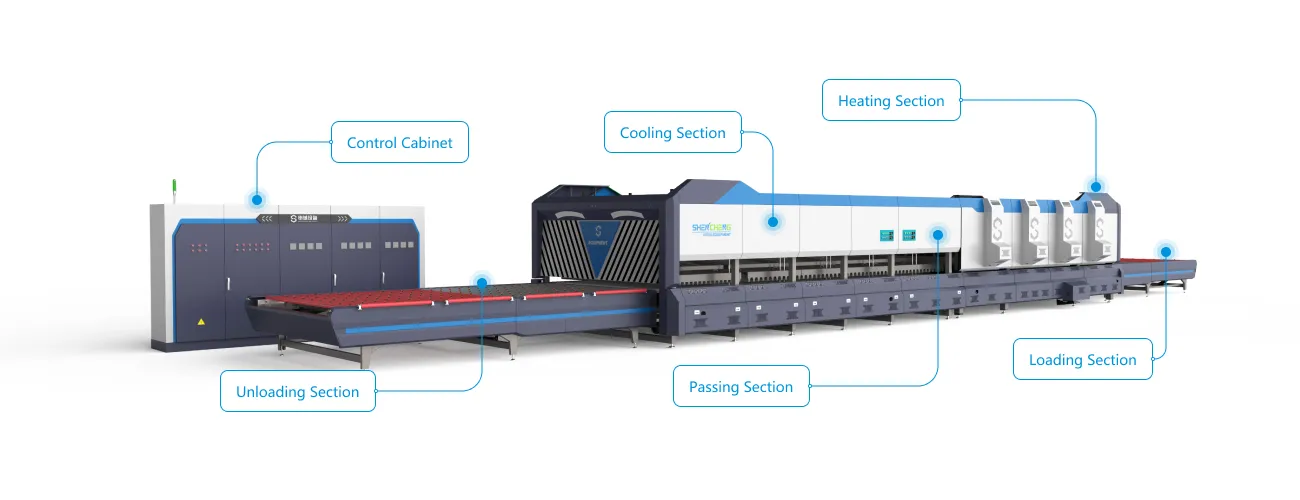

Los hornos de templado de vidrio varían en tamaño, capacidad y características según las necesidades específicas del fabricante de vidrio. Los hornos avanzados pueden incorporar tecnologías como calentamiento por convección, radiación infrarroja o sistemas de control computarizados para lograr perfiles precisos de calentamiento y enfriamiento y optimizar la eficiencia energética.

El vidrio templado producido por estos hornos se usa ampliamente en diversas aplicaciones, incluidas ventanas, puertas, mamparas de ducha, fachadas de vidrio, ventanas de automóviles y muebles. Sus características de mayor resistencia y seguridad hacen que sea menos probable que se rompa en fragmentos afilados y peligrosos cuando se somete a un impacto o tensión, lo que lo hace ideal para su uso en entornos donde la seguridad es primordial.