Advantages of Forced Convection:

Uniform Heating: The forced air circulation enables consistent temperature distribution, reducing optical distortions and stress variations.

Energy Efficiency: By improving heat transfer efficiency, forced convection furnaces often consume less energy than traditional radiant heating methods.

Versatility: Suitable for tempering both thin and thick glass, as well as low-emissivity (Low-E) glass, which can be challenging to temper using conventional methods.

Quality Improvement: Glass treated with forced convection typically has fewer defects, making it ideal for high-precision applications.

Applications:

Architectural Glass: Used in structural and aesthetic building elements, such as windows, facades, and glass walls.

Automotive Glass: Ideal for producing strong, safe car windows.

Solar Panels and Electronics: Often used for glass that requires high precision and low distortion.

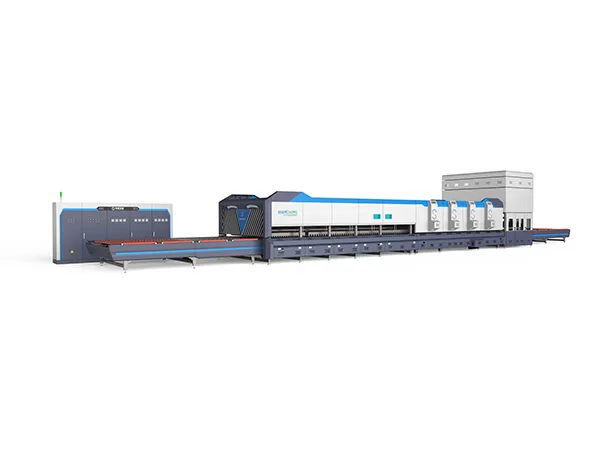

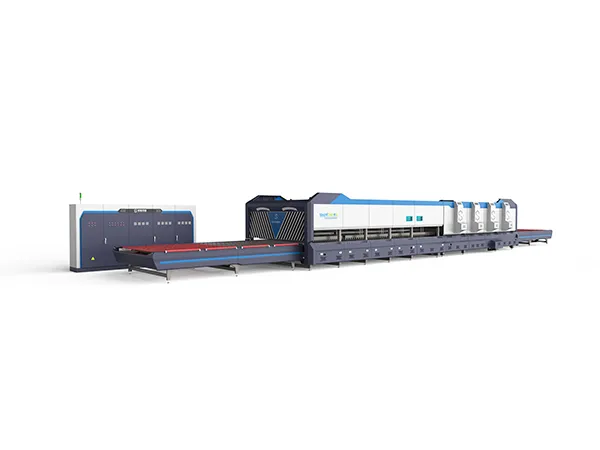

Heating Phase: Glass sheets are placed on rollers and enter the furnace. Inside, hot air is circulated around the glass by powerful fans or blowers, which distribute the heat more evenly compared to natural convection.

Temperature Uniformity: Forced convection minimizes temperature gradients, reducing issues like warping or uneven strength that can occur with inconsistent heating.

Quenching Phase: After reaching the desired temperature (around 600-650°C), the glass moves into the quenching area, where it's rapidly cooled by blasts of air, hardening the surface and creating tempered glass.

Forced convection technology can fully and evenly heat each piece of glass, especially in heating white glass and three silver Low-E glass with significant advantages.

The use of Siemens temperature control module and PID intelligent heating control technology makes the temperature response faster and the temperature control more intelligent, and can flexibly form various heating curves to meet the demanding glass heating requirements.

Unique heat preservation technology and the use of high-quality heat preservation materials reduce the heat conduction of the metal fixtures inside the furnace, reduce power consumption, and at the same time, make the furnace structure robust and durable, and greatly extend the effective life.

Adopting computer simulation technology and aerodynamic principle to form a unique toughening and cooling system, which makes the toughened products reach the world's advanced level in terms of both appearance quality and inner quality.

Intelligent control and digital production integrate the functions of equipment processing parameter setting, glass parameter identification, real-time monitoring of the processing process and automatic regulation and control, which improves the control accuracy and emergency response speed of the equipment.