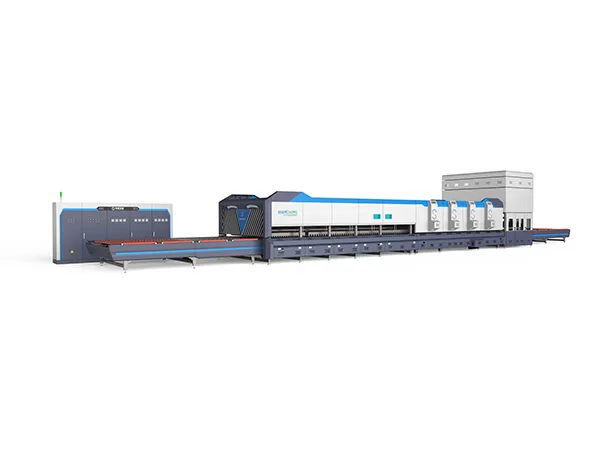

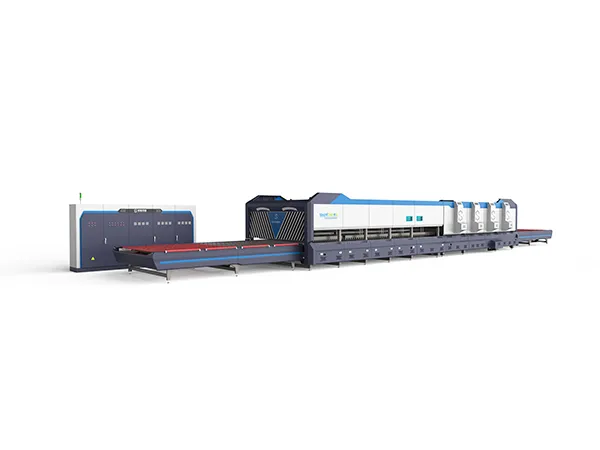

The flat bend glass tempering furnace occupies an important position in the glass processing industry due to its efficient heating technology, precise temperature control and wide range of applications.

Key Features of Flat Bend Glass Tempering Furnaces

Heating System: Uses electrical or gas heaters to heat glass to the required tempering temperature (around 600-700°C). The heating is typically uniform to prevent thermal stress and ensure high-quality tempering.

Bending Capability: Allows for bending of glass while heating, which is essential for curved glass applications in automotive windshields, railings, and building facades.

Quenching System: After heating, the glass is rapidly cooled in a controlled environment using high-pressure air blowers. This process "tempers" the glass, increasing its strength and making it safer by causing it to break into small, less harmful pieces if shattered.

Conveyor System: Transports the glass through the furnace, ensuring smooth handling and even heating. Some models offer adjustable conveyor speeds for precise control.

Computerized Control System: Modern tempering furnaces are often equipped with digital controls, allowing operators to program and monitor temperatures, quenching rates, and bending parameters for consistency and precision.

Versatility: These furnaces can handle various glass thicknesses and types, including clear, tinted, and coated glass, making them adaptable for different industries.

Applications of Flat Bend Glass Tempering Furnaces

Automotive: Tempered curved glass for windshields and side windows.

Architectural: Bent glass for skylights, canopies, railings, and building facades.

Decorative: Furniture and artistic applications where both durability and design flexibility are required.

The working principle of a flat bending glass tempering furnace involves a combination of controlled heating, bending, and rapid cooling (quenching) to strengthen the glass. Here’s a step-by-step breakdown of the process:

1. Glass Loading

Flat glass sheets are loaded onto a conveyor belt or roller system at the beginning of the furnace. The conveyor transports the glass through each stage of the tempering process.

2. Heating Stage

The glass is transported into the heating chamber, where it is gradually heated to the tempering temperature, typically between 600°C and 700°C (1112°F to 1292°F).

Heaters (either electric or gas-powered) ensure even heating across the glass surface. Uniform heating is crucial to avoid internal stresses.

The duration and temperature are carefully controlled and adjusted based on glass thickness and type.

3. Bending Process (for Bent Glass)

For curved glass, bending occurs in this stage within the furnace.

Gravity Bending: Some furnaces allow the glass to bend naturally under its own weight, using specially designed molds or rollers.

Press Bending: In some designs, press molds are used to shape the glass to a specific curvature while it is hot.

This shaping capability allows the furnace to produce curved glass required in automotive or architectural applications.

4. Transfer to the Quenching Zone

Once the glass reaches the target temperature and, if necessary, the desired bend shape, it moves to the quenching section.

The glass is rapidly transferred to the quenching zone to avoid heat loss or deformation.

5. Quenching (Rapid Cooling)

In the quenching section, high-pressure air jets cool the glass quickly from both sides. This rapid cooling process is crucial as it creates a tempering effect.

The outer layers of the glass cool faster than the inner layers, leading to compressive stresses on the surface and tensile stresses within the core. This combination enhances the strength and durability of the glass.

6. Unloading and Quality Inspection

The tempered glass exits the furnace and is inspected for quality, shape, and surface finish. This final inspection ensures that the glass meets safety and strength standards.

After quality control, the glass can be packaged and prepared for delivery.

Key Concepts in the Working Principle

Thermal Uniformity: Ensuring even heating across the glass surface is essential to prevent warping or uneven tempering.

Stress Formation: The rapid cooling process is what creates the compressive and tensile stresses, giving tempered glass its strength.

Control Systems: Modern furnaces often have computerized systems to monitor and adjust temperature, quenching speed, and bending accuracy for different glass specifications.