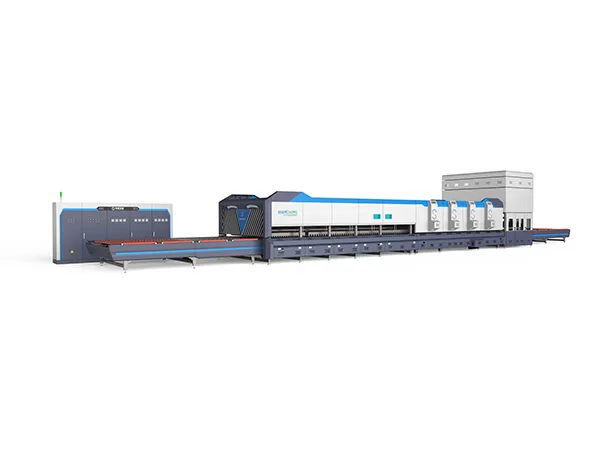

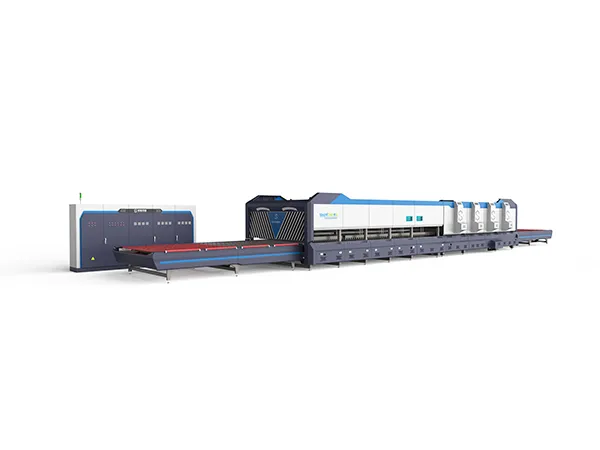

Advantages of a Double Chamber Tempering Furnace

Increased Production: The two chambers enable continuous operation, allowing one chamber to start processing the next sheet while the other finishes the tempering process.

Energy Efficiency: Having two chambers minimizes energy loss, as one chamber can maintain a constant temperature even if one is on standby.

High Quality: Enhanced control over temperature and cooling leads to more consistent results, reducing distortion and surface imperfections.

How a Double Chamber Glass Tempering Furnace Works

Heating Process: Glass sheets are loaded onto rollers and enter the first chamber, where they’re gradually heated to a temperature of about 600-650°C (1112-1202°F). The second chamber is then used to fine-tune and control the glass temperature to ensure uniform heating.

Quenching: After reaching the appropriate temperature, the glass is rapidly cooled using high-pressure air blowers in a process known as quenching. The rapid cooling causes the glass surface to compress, making it up to four to five times stronger than untreated glass.

Tempering Process Control: The double chamber setup allows manufacturers to optimize the heating and tempering process for various glass thicknesses and types by controlling each chamber independently.

Applications

Architectural Glass: Used for windows, facades, and doors.

Automotive Glass: Car windows and sunroofs.

Furniture and Appliances: Used in tabletops, oven doors, and shower enclosures.