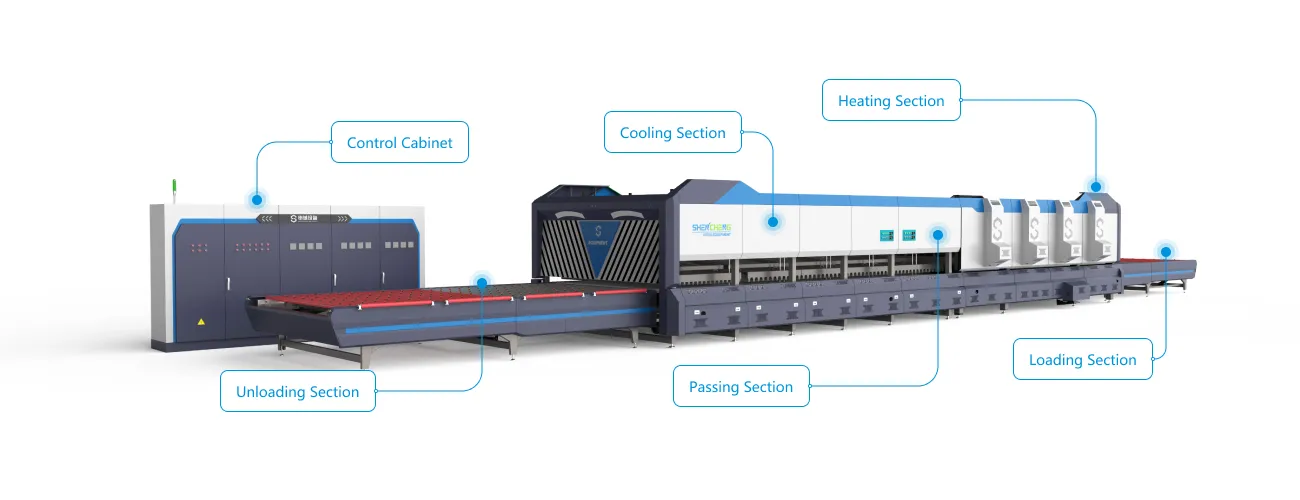

A glass tempering furnace is a specialized piece of equipment used in the glass manufacturing industry to temper glass, making it stronger and safer than untreated glass. Tempering involves heating the glass to a high temperature and then rapidly cooling it to create internal stresses, resulting in increased strength and durability.

Glass tempering furnaces vary in size, capacity, and features depending on the specific needs of the glass manufacturer. Advanced furnaces may incorporate technologies such as convection heating, infrared radiation, or computerized control systems to achieve precise heating and cooling profiles and optimize energy efficiency.

Tempered glass produced by these furnaces is widely used in various applications, including windows, doors, shower enclosures, glass facades, automotive windows, and furniture. Its increased strength and safety features make it less likely to break into sharp, dangerous shards when subjected to impact or stress, making it ideal for use in environments where safety is paramount.