A flat glass tempering furnace is a specialized industrial machine used to heat and cool flat glass sheets in a controlled manner, enhancing their strength and safety properties. Here’s an overview of the process and key features:

Overview of the Tempering Process

Heating:

The glass sheets are heated to a temperature of approximately 620-680 degrees Celsius (1148-1256 degrees Fahrenheit), which is near the glass's softening point.

The heating is done uniformly to ensure even temperature distribution across the entire glass sheet.

Quenching:

After reaching the desired temperature, the glass is rapidly cooled using high-pressure air jets.

The rapid cooling causes the surface of the glass to solidify quickly while the interior remains slightly warmer and more fluid for a short time.

This process creates compressive stresses on the surface and tensile stresses in the interior, giving the tempered glass its strength.

Key Features of a Flat Glass Tempering Furnace

Heating Section:

Usually consists of electric heating elements or gas burners.

Equipped with precise temperature control systems to maintain uniform heating.

Quenching Section:

Comprises a series of air nozzles that blow high-pressure air onto the heated glass.

Designed to cool the glass rapidly and uniformly.

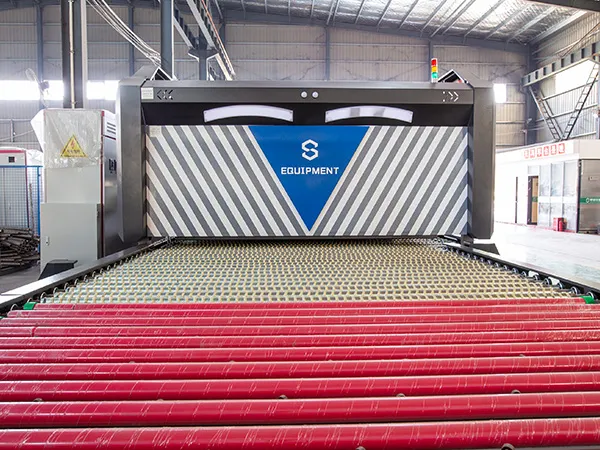

Conveyor System:

Transports the glass sheets through the heating and quenching sections.

Made of materials that can withstand high temperatures and mechanical stress.

Control System:

Advanced computer systems control the entire process, ensuring precise temperature management and air flow.

Often includes sensors and feedback mechanisms to monitor and adjust parameters in real time.

Safety Features:

Safety interlocks and emergency shutdown systems.

Protective barriers and insulation to prevent accidental contact with hot surfaces.

Applications

Architectural Glass: Used in buildings for windows, facades, and glass doors.

Automotive Glass: Windshields, side windows, and rear windows.

Furniture and Appliances: Glass tops for tables, shelves, and doors for appliances like ovens and refrigerators.

Advantages of Tempered Glass

Increased Strength: Tempered glass is approximately four to five times stronger than standard annealed glass.

Safety: When broken, it shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury.

Thermal Resistance: Better withstands thermal stresses and temperature variations.

Considerations

Size Limitations: The size of the furnace determines the maximum dimensions of the glass that can be tempered.

Edge and Surface Quality: Proper handling and processing are crucial to maintaining the quality and strength of the tempered glass.

Overall, flat glass tempering furnaces are essential for producing high-strength, safe glass products used in various industries.