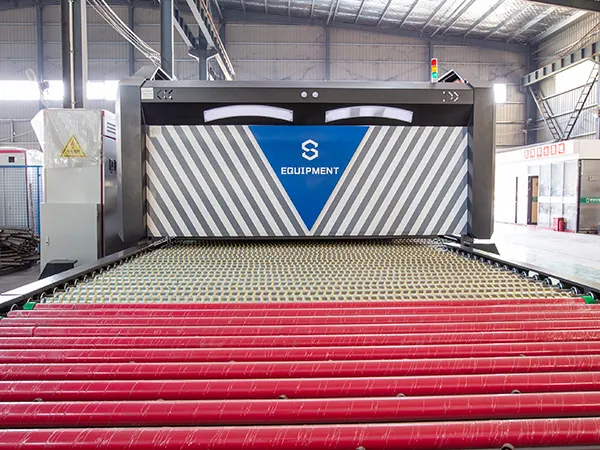

فرن تقسية الزجاج عبارة عن قطعة متخصصة من المعدات المستخدمة في صناعة الزجاج لتلطيف الزجاج، مما يجعله أقوى وأكثر أمانًا من الزجاج غير المعالج. تتضمن عملية التقسية تسخين الزجاج إلى درجة حرارة عالية ثم تبريده بسرعة لخلق ضغوط داخلية، مما يؤدي إلى زيادة القوة والمتانة.

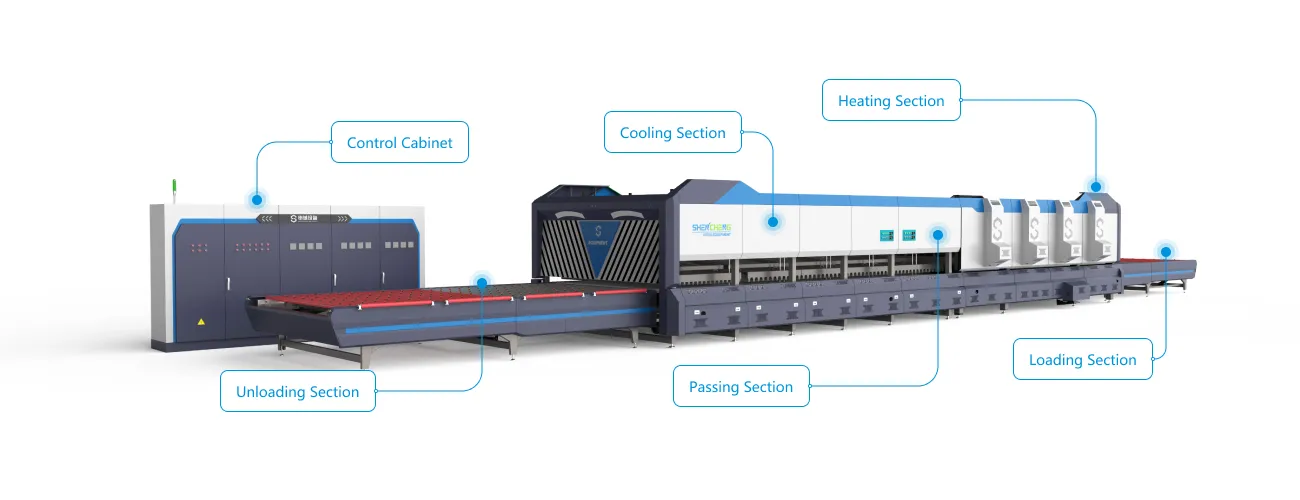

تختلف أفران تقسية الزجاج من حيث الحجم والسعة والميزات وفقًا للاحتياجات المحددة للشركة المصنعة للزجاج. قد تشتمل الأفران المتقدمة على تقنيات مثل التسخين بالحمل الحراري، أو الأشعة تحت الحمراء، أو أنظمة التحكم المحوسبة لتحقيق خصائص دقيقة للتدفئة والتبريد وتحسين كفاءة الطاقة.

يتم استخدام الزجاج المقسى الذي تنتجه هذه الأفران على نطاق واسع في العديد من التطبيقات، بما في ذلك النوافذ والأبواب ومقصورات الاستحمام والواجهات الزجاجية ونوافذ السيارات والأثاث. إن ميزات القوة والسلامة المتزايدة تجعله أقل عرضة للكسر إلى شظايا حادة وخطيرة عند تعرضه للتأثير أو الضغط، مما يجعله مثاليًا للاستخدام في البيئات التي تكون فيها السلامة أمرًا بالغ الأهمية.